Advantages

- High thermal insulation value

- 100% fire proof economy in cost

- Easy application

- Sound proof

- Prevents ingress of heat

- Protects concrete slb cracking

- Reduces the weight as filling material where structural problems arise.

The remarkable fire-proofing and insulating properties of Hemalite coupled with its weight saving value make it much more efficient than any other light weight in the preparation of insulating concrete.

The thermal insulating properties of Hemalite prevent the ingress of heat from the sun’s rays during summer and reduce heat loss during winter, consequently, expansion and contraction in buildings is minimized and concrete roof slabs are protected from cracking that take place when exposed to temperature changes.

For roofs of large area, falls can be effected without appreciably adding to the total weight of the roof.

|

TECHINICAL DATA OF HEMALITE INSULATING CONCRETE |

|||

| FLOCH SCREEDS / FILLING MATERIAL | ROOF INSULATION | ||

| MIXES | |||

| CEMENT | 1 BAG | 1 BAG | |

| HEMALITE | 3 BAG | 4 BAG | |

| WATER | 50 TO 60 LT | 70 To 80 LT | |

| PROPERTIES

DENRITY OF HEMALITE INSULATING CONCRETE KGS./Cu.M. 1 BS/CFT |

400 TO 480

25-30 |

320-400

20-25 |

|

| K FACTOR EXPRESSED IN KCAL/M/M2/HR/1C

BTU/1”/SFT/HR/1F |

0.084

0.68 |

0.072

0.58 |

|

| COMPRESSIVE STRENGTH OFHEMALITE SCREED (WITHOUT TOPPING)

KGS./SQ.CM. 1BS./SQ.IN. |

9-16 KGS

125-225 |

7-9 KGS

100-125 |

|

| MAXIMUM CONCENTRATED LOAD (WITH TOPPING) KGS./SQ.CM. 1BS./SQ.IN. | 53 KGS

750 IBS. |

42 KGS

600 lBS |

|

| (FOR ONE CUBIC METERS VOLUME) / REQUIREMENT OF MATERIAL | CEMENT | HEMALITE | WATER |

| FOR FLOOR SCREEDS/ FILLING UP PURPOSE | 5.8 BAGS | 17.5 BAGS | 220 TO 240

LIT |

| FOR ROOF INSULATION | 4.3 BAGS | 17.5 BAGS | 220 TO 240

LIT |

|

RECOMMENDED THICKNESS IN BULINDING FOR ROOF INSULATION |

|||

| 50 MM (2”) | FOR SLOPE CONCRETE RESIDENTIAL BUILDINGS | ||

| 175 MM (3”) | FOR SLOPE / PLAIN CONCRETE RESIDENTIAL BUILDINGS | ||

| 100 MM (4”) | FOR AIR CONDITIONED BUILDINGS

FOR TECHNICAL AIR CONDITIONED BUILDINGS |

||

| 125 MM (5”)

MAXIMUM |

THICKNESS CAN BE VARIED TO OBTAIN THE DESIRED SLOPE | ||

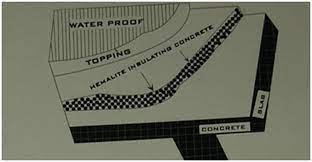

SPECIFICATION OF LAYING “HEMALITE” FIRE PROOF INSULATING CONCRETE

INSTRUCTIONS FOR LAYING HEMALITE INSULATING CONCRETE

A. The upper surface of the roof shall Be wire brushed and cleaned of all Dust and foreign matters.

B. Hemalite insulating concrete Consisting of 1 (one) bag of cement And 4 (four) bags of Hemalite shall be Laid for a thickness as indicated on Drawings, Hemalite manufactured By M/s Hemalite products Pvt. Itd. Chennai

C. Over the Hemalite insulating Concrete apply 25 mm thick screed Concrete.

D. Curing should be done-on screed Concrete for minimum of 7 days By sprinkling water.

E. Over the Hemalite insulating Concrete water proofing course Should be done as specified in the Drawings.